This “Applications” search mechanism is currently being populated with content, thank you for your patience while we work to provide this service.

Please head to the capabilities search page in the meantime, or contact us with an enquiry.

A few flagship capabilities are listed below to show you how this functionality will work in the future

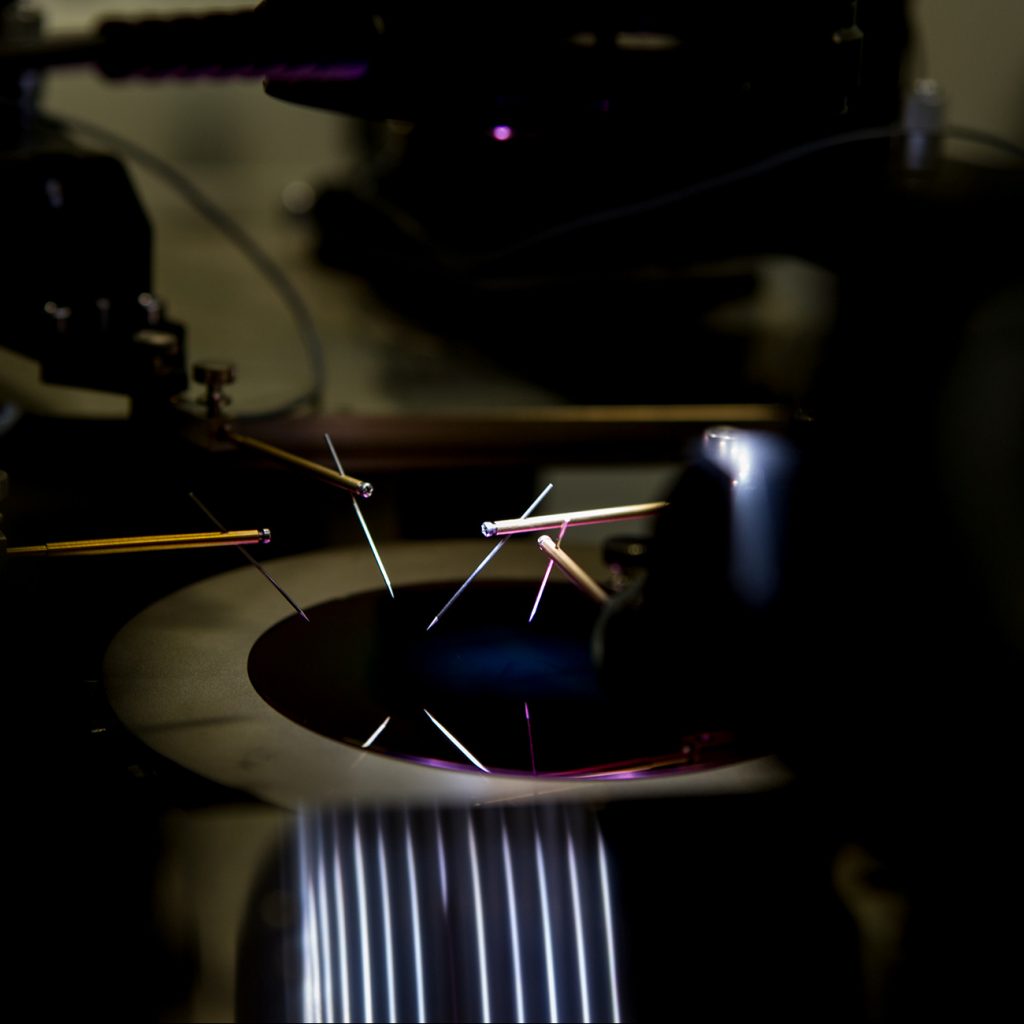

Electron Beam Lithography (EBL) allows users to write patterns with extremely high resolution, smaller than 10nm in size. It makes use of a highly energetic, tightly focused electron beam, which is scanned over a sample coated with an electron-sensitive resist. The electron beam scans the image according to a…

3D additive biofabrication reapplies the layer-by-layer method of 3D printing to produce living tissues.

One prominent technique involves printing layers of a biocompatible substance called a hydrogel that has been infused with a patients stem cells. Once a 3D structure has been printed, stem cells can proliferate…

MPCVD is a chemical vapour deposition process which uses a continuous microwave source to create and help to maintain a highly reactive plasma made up of the reacting chemicals and necessary catalysts.

MPCVD is heavily used in the ANFF network to deposit layers of diamond – methane and hydrogen are introduced and…

Thermal Scanning Probe Lithography (t-SPL) is a 3D direct-write lithography technique that provides sub-10nm resolution with sub-2nm vertical accuracy in ambient conditions.

A 1,000°C cantilevered tip sublimates PPA resist as it scans over a sample, before the tip quickly cools to provide real-time topological…

CNC milling is a conventional manufacturing technique that uses a computer to control a milling cutter.

It can be used to precisely machine geometries and features into a substrate, or to mill hot embossing stamps and jigs that may be used to fabricate microstructured features in devices.

The equipment typically…

MOCVD is a chemical vapour deposition technique that uses metal-organic precursors to enable the growth of III-V semiconductors in two and three dimensions.

Once a bulk glass material has been produced, it has to be made into something useful. If the aim is to produce some sort of fibre optic, draw towers are used to create glass fibres by heating and stretching a bulk material (or preform) to create long strands. The design and composition of this preform results in…

Molecular Beam Epitaxy is a deposition technique that allows for crystals to be grown with extremely high purity. The process allows for subnanometre control over the structure of the crystal as it’s grown and positioning of dopants within the material, as well as film thickness.

A series of molecular beams are…

Roll-to-roll printing is a technique that is widely used to print newspapers, magazines and many other conventional printed products that are required in large quantities.

The ANFF equipment is based on this principle but allows for the user to print functionalised inks onto novel materials – it’s already…

Developed by the University of Newcastle in collaboration with researchers from Cambridge University, the Newcastle Scanning Helium Microscope (SHeM) is an extremely surface-sensitive imaging technique. The tool, one of only three in the world, probes samples using neutral helium atoms instead of the more…