Home > News & Events > Storing sunshine in a bottle

ANFF-enabled researchers at ANU have created a record- breaking device that uses sunlight to harvest hydrogen.

This exciting research is a major step in the pursuit of a clean- power economy, and aligns closely with the Council of Australian Governments (COAG) Energy Council’s national hydrogen strategy.

Many countries have recognised the incredible potential of hydrogen as a clean source of energy – it’s a transportable, exportable clean fuel with a high specific energy density, and efficiently produces electricity when consumed in a fuel cell, producing water as the only byproduct.

While it’s the most common element in the universe, hydrogen is oddly difficult to gather efficiently. Most of the Earth’s hydrogen is bound up in in molecules like water, it can be separated and collected but this requires energy.

A promising mechanism for hydrogen harvesting is by splitting water in a process called electrolysis. The process uses electricity to break apart water into hydrogen and oxygen, the hydrogen can then be captured, stored, and used as a fuel source as and when it’s needed.

Electrolysis requires power and until now this has meant pulling on the national grid, requiring a great deal of additional infrastructure and resulting in a lot of lost energy, reducing overall efficiency.

However, the ANU team has now demonstrated record-breaking conversion efficiencies of hydrogen harvesting by creating a standalone system that powers itself. They’ve introduced a tandem solar cell system that feeds electricity directly into a water-splitting chamber and removes the need for external power sources.

“To produce hydrogen in the past, solar plants had to produce electricity which is then used to electrolyse water to produce hydrogen. Our new method is more direct, making it more efficient,” lead author of the research, Dr Siva Karuturi said.

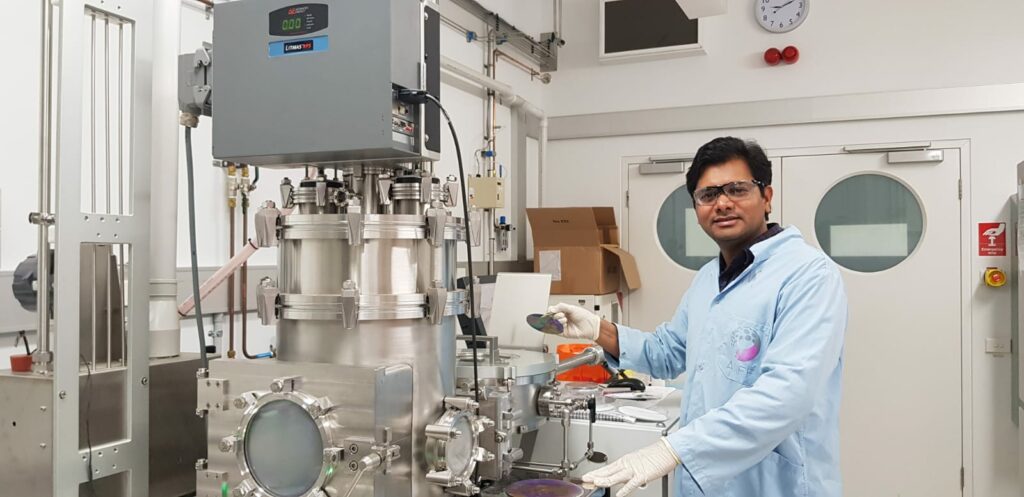

The team worked with ANFF-ACT to build two interlinked solar absorbers capable of generating the required energy levels to separate hydrogen. The first cell is made of a perovskite material, these are considered to be some of the best performing photovoltaic materials available and allows the team’s device to accumulate part of the power required for the electrolysis process. Then, a second silicon photoelectrode kicks in to supply a sufficient voltage to allow the splitting to begin.

This direct solar-to-hydrogen approach has unlocked record- breaking conversion efficiencies of 17.6%, nearing the performance of current rooftop solar panels. The team’s planned steps could see them reach the 20% efficiency mark before the end of 2021, paving the way for cost-effective green hydrogen production.

“Significant cost benefits could be achieved through the use of the solar-to-hydrogen approach,” says Dr Karuturi, “as it avoids the need for added power and network infrastructure necessary when hydrogen is produced using a traditional electrolyser. By avoiding the need to convert solar power from DC to AC power and back again, in addition to avoiding power transmission losses, the direct conversion of solar energy into hydrogen can achieve a higher overall efficiency for the total process.”

While they begin taking steps towards higher efficiencies, Dr Karuturi and the team will also look to incorporate cheaper materials to further reduce costs of the technology.