The advent of light-responsive 4D-printed liquid metal/polymer nanocomposites is paving the way for a new generation of laser-controlled soft robots.

Robots are designed to perform tasks automatically in response to stimuli or other inputs. Engineers have long relied on rigid materials like metals and hard plastics to create ‘hard’ robotic systems. These conventional robots, while effective, lack the flexibility and adaptability required for more nuanced tasks.

Enter soft robots that can bend, stretch and deform in ways hard robots cannot. This flexibility allows soft robots to interact more naturally with the human body, mimicking soft human tissues like joints and cartilage.

Innovative materials are key to the construction of soft robots and require a different approach to manufacturing. Conventional robot fabrication techniques, such as drilling and milling, are unsuitable for making soft robots. Instead, 3D printing is employed to create a soft robot layer by layer. This method offers advantages in customising the structure of materials and designing intricate structures while offering cost-effective and time-saving benefits.

However, conventional 3D-printed polymers are fixed in shape once printed, limiting their utility in applications that require adaptability. This is where 4D printing comes into play.

4D printing involves creating 3D-printed objects that can transform their shape over time – introducing a ‘fourth dimension’ – when exposed to certain stimuli.

Many printed polymers display limited responses to external stimuli such as light, electricity and magnetic fields, limiting their utility in 4D printing applications.

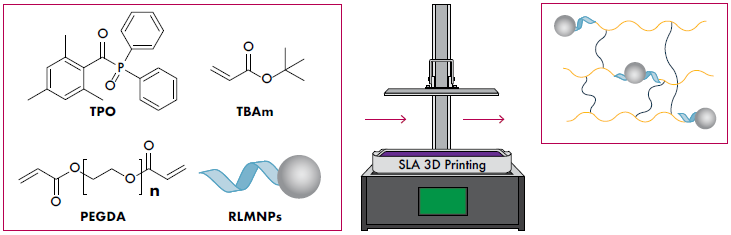

The key to a successful 4D-printed device is the addition of specific ingredients to the printer ink that give the finished product new qualities and abilities capable of change when stimulated.

The integration of functional nanomaterials into 3D-printed polymers presents several benefits for advancing 4D-printed soft robots. Nanoparticles with unique properties, such as photosensitivity and chemosensitivity, can enhance the stimuli responsiveness of printed objects, allowing for precise and efficient shape changes.

University of Queensland researchers Dr Liwen Zhang, Dr Ruirui Qiao and Prof Tom Davis from the Australian Institute for Bioengineering and Nanotechology have introduced a novel method for creating 4D-printed liquid metal polymer nanocomposites with shape memory capabilities. The team’s nanocomposite materials can be coaxed into performing a range of mechanical tasks using near-infrared (NIR) lasers.

Their unique soft robot combines gallium-indium (Ga-In) liquid metal nanoparticles (LMNPs), which absorb NIR and convert the energy to heat, with a biocompatible polymer that responds to heat by transitioning to a rubber-like state. Their LMNPs can be directly prepared in various 3D-printed resins, providing a simple and effective one-step printing approach for fabrication.

The sturdy 4D-printed soft robots are capable of bending, grasping, lifting and releasing objects weighing up to 5 times their own weight, while also being able to return to their resting shape.

ANFF-QLD is partnering with these researchers to create truly tiny soft robots. ANFF’s Nanoscribe 3D printer can print soft robots at sizes below 1 mm. The ability to customise and shape small-scaled, soft and intelligent materials through 4D printing will lead to wider manufacturing breakthroughs and innovations.

The possibilities for this kind of technology are only limited by our imaginations. Soft robots can serve as coronary stents, artificial muscles, tendons or ligaments, and adaptive prosthetics. This is possible because NIR lasers can penetrate body tissues, allowing a soft robot to be inserted in one shape and then triggered to change into its final functional form.

The future of robotics lies not just in artificial intelligence but in the innovative materials that make robotic advancements possible. Material science is a critical component in the development of soft robotics, and continued innovation in this field will expand the range of what future robots can achieve.

Published 15 October in ANFF’s 2024 Casebook ‘ANFF NEXT‘

Posted 04 August 2025