Providing the spark for richer soil

Pioneering engineers have redesigned plasma microreactors to transform hydrogen or air into customised fertilisers.

Fertilisers are essential for enhancing crop yields and ensuring food security, making their availability crucial for Australian agriculture. A large part of our fertiliser is imported, including all of Australia’s granular urea supply for nitrogen-based fertilisers, over 110 million tonnes annually from the Middle East, Southeast Asia and China.

The fertiliser supply chain is vulnerable to world events. For example, in 2022, the Nord Stream pipelines that transport natural gas from Russia to Europe were sabotaged, and 20% of the global ammonia (NH3) supply disappeared overnight.

Developing sovereign capability in fertiliser production is critical for Australian agriculture. Currently, ammonia is produced by the Haber-Bosch method from hydrogen extracted from natural gas and nitrogen from air. The process is centralised, highly energy-intensive and relies heavily on natural gas, producing carbon dioxide (CO2) emissions that lead to approximately 3% of the world’s carbon emissions.

Efforts are being made to develop more sustainable methods, such as using a plasma-assisted chemical reaction with renewable hydrogen, to reduce the environmental impact of ammonia production.

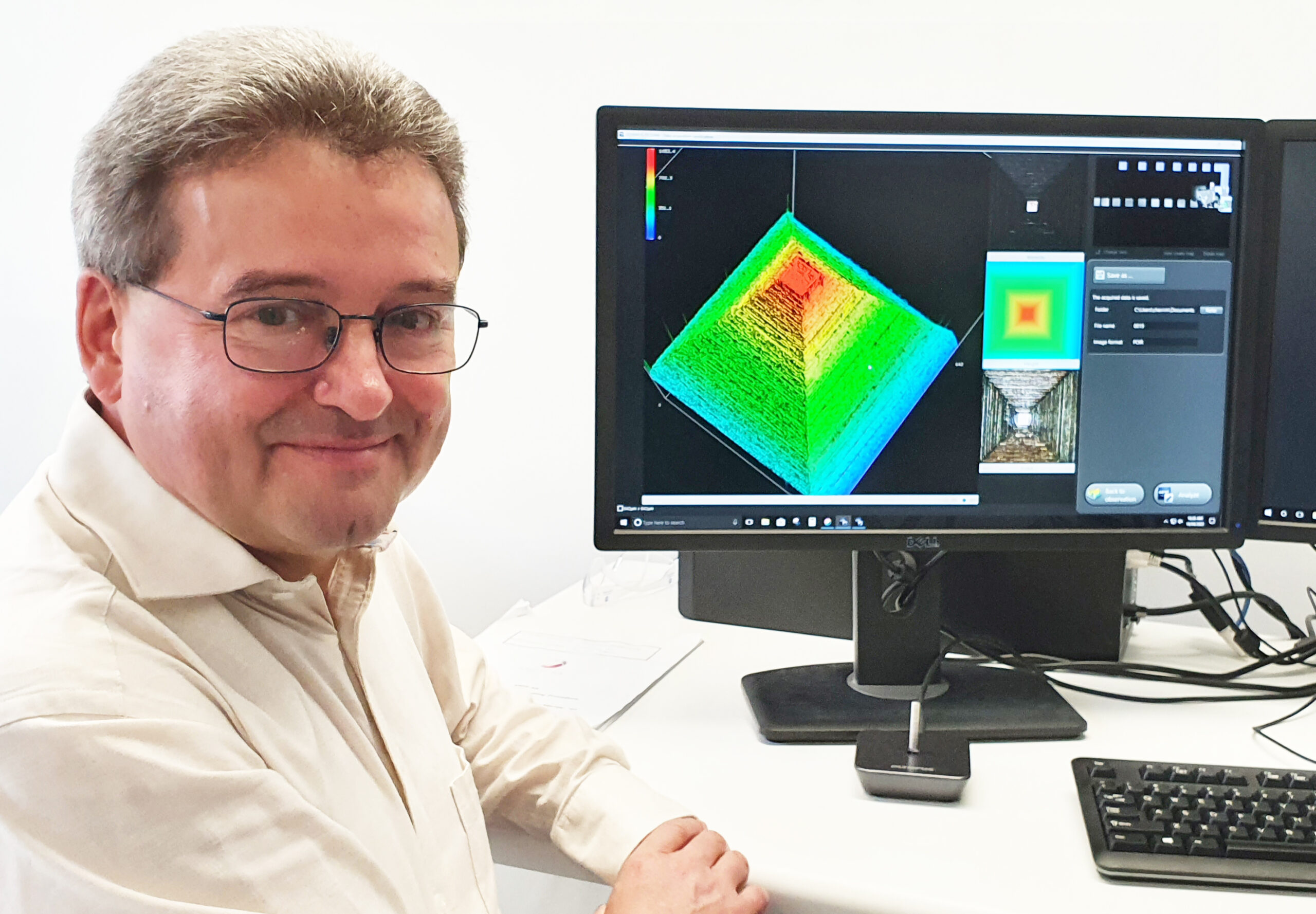

At the forefront of these innovations are Prof Volker Hessel and his team at the University of Adelaide and the University of Warwick. They have exploited uniquely designed micropyramid-disk plasma reactors to produce customised nitrogen-based fertilisers for Australian farmers.

A microplasma reactor is a device that generates tiny, highly energised gas plasmas confined to small spaces to drive chemical reactions efficiently.

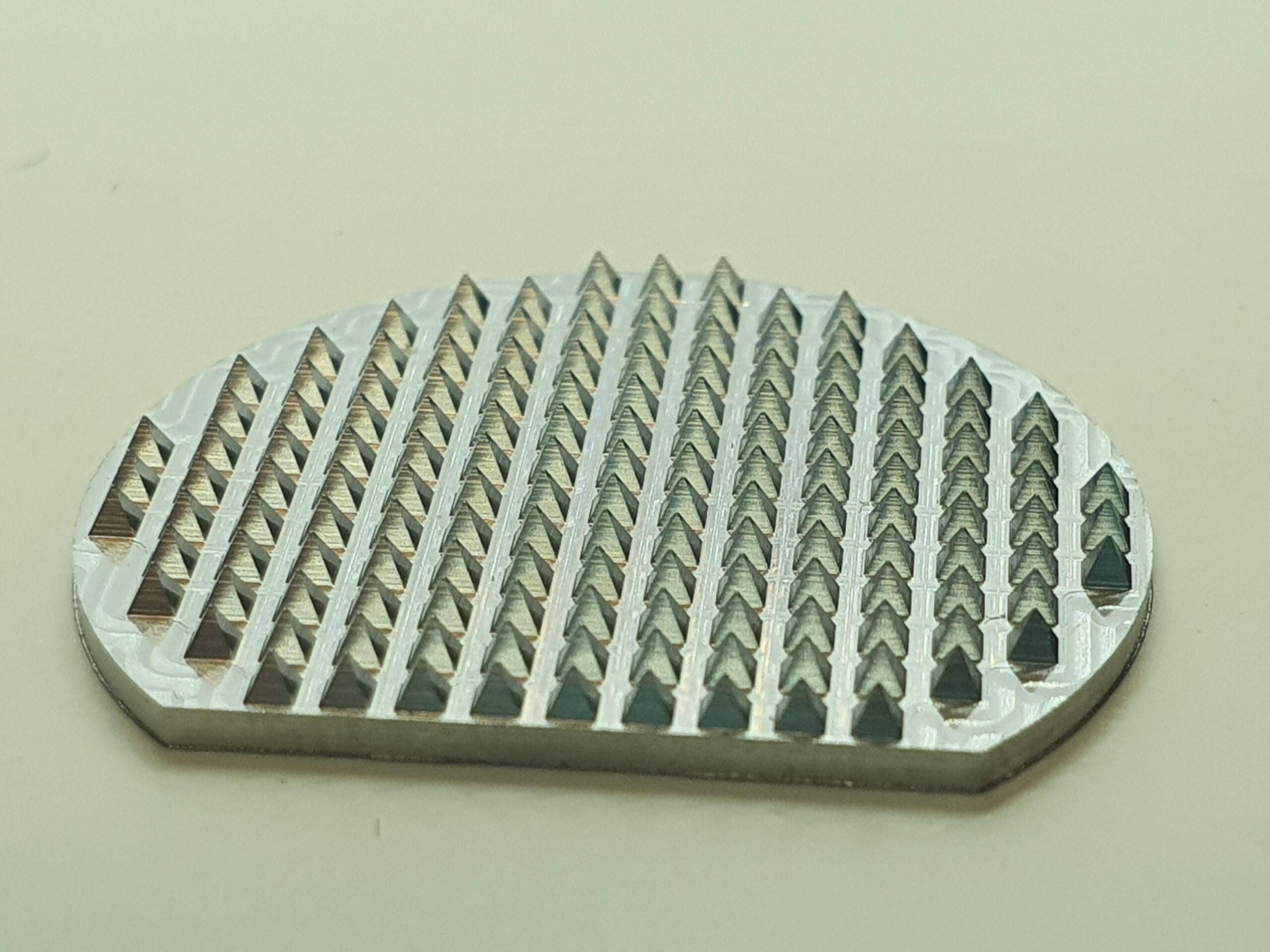

Conceptualised by Warwick’s Prof Evgeny Rebrov and Dr Nima Pourali, their pyramid-shaped electrode design narrows the electrode gaps to less than one millimetre and focuses the plasma energy at the tiny tips.

These small, stable charge points allow energy to spread efficiently through intensified electric field zones, making the conversion of hydrogen and air into NH3 more effective. This process significantly reduces energy consumption and emissions compared to traditional flat electrodes, offering a more economical solution for ammonia production.

The first fully functional prototype of this microreactor was crafted using the capabilities available at ANFF-SA.

Having the microreactors machined locally by world-leading microfabrication experts saved the research team significant time and costs during their experimental work, while increasing project output and innovation. The pyramid-shaped electrodes were ideal for basic study of the chemical process and secured long-term funding for alternative plasma microreactor development.

Plasma microreactors can be scaled up to production scale for distributed manufacturing, like their flow chemistry counterparts in pharmaceutical industrial production, providing the means for locally or regionally produced ammonia that could free Australian agriculture from external global forces that affect availability and price.

Prof Hessel is partnering with Australian AgTech companies FarmN in Adelaide and Plasma-Leap in Sydney to commercialise the plasma-fertiliser technology. A field trial of an N-fertiliser-producing benchtop reactor has been installed in the Clare Valley in South Australia at a Seppeltsfield vineyard.

Plasma technology will revolutionise Australia’s fertiliser industry by enabling on-site production, reducing reliance on traditional supply chains and aligning with sustainability goals. While cultural and technological shifts are necessary for adoption, Australian farmers are known for their openness to innovation, making this transition promising and impactful for the future of agriculture.

Published 15 October 2024 in ANFF’s 2024 Casebook ‘ANFF NEXT‘

Posted 2 December 2024