Rolling out solar

Kardinia Energy’s innovative printed solar technology will revolutionise solar installations, making them viable for previously unsuitable commercial and industrial spaces.

As of early 2023, over 3.4 million traditional silicon solar power systems have been installed on Australian homes and small businesses, continuing the technology’s widespread adoption in this country.

However, some roofs simply aren’t suitable for solar panel installation due to their orientation or structural integrity. Many industrial roof spaces can’t take the weight of traditional solar panel arrays, which weigh 20 kilos per square metre, including 100 million square metres of low weight-bearing rooftops in Australia and 4 billion globally.

Kardinia Energy’s next generation low-weight, flexible, printed solar will expand solar installation into previously unsuitable spaces. This technology has been developed for over 25 years at the University of Newcastle led by Prof Paul Dastoor and his team at the Centre for Organic Electronics.

Kardinia Energy’s solar panels use organic photovoltaic (OPV) materials, a fairly recent advancement. Unlike silicon-based panels, their printed solar panels consist of organic semi-conducting polymers on recyclable PET plastic. These materials are abundant and avoid the energy-intensive manufacturing of silicon panels.

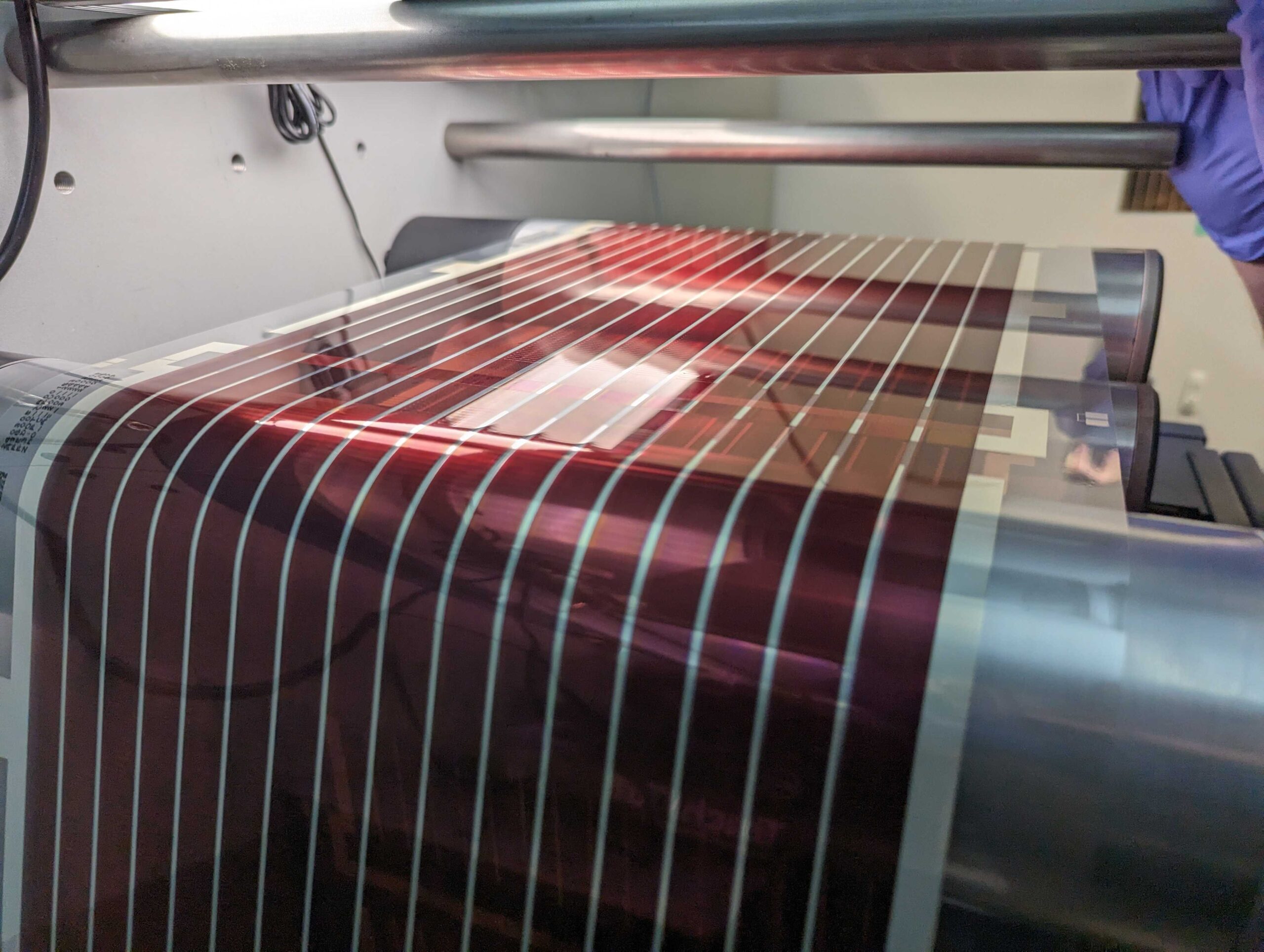

Printed solar technology employs a special ink that converts light into electricity. The solar ink contains semiconductor materials and electrodes necessary for generating solar energy.

This solar ink is printed onto flexible surfaces such as plastic using commercial roll-to-roll (R2R) printers, like those for printing newspapers.

The resulting printed solar panels are as thin as a sheet of paper and weigh only 300 grams per square metre. The low cost of production is another significant advantage. Printed solar can be made at a cost of less than US$10 per square metre.

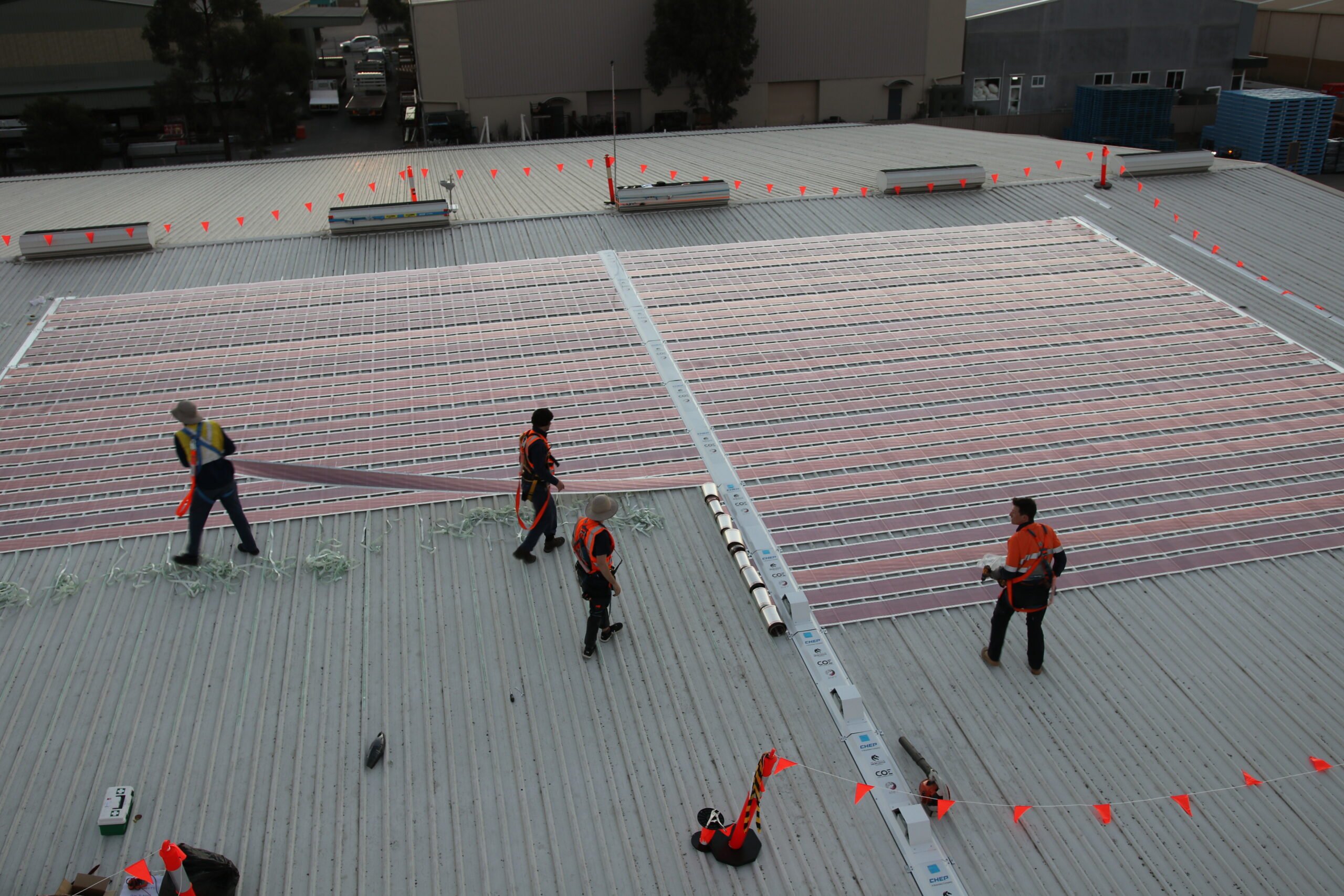

The biggest impact of this technology is expected in the commercial and industrial space. Kardinia Energy’s printed solar is distinguished by its lightweight nature, making it ideal for structures that cannot support the weight of traditional solar panels, such as commercial and industrial rooftops.This innovation addresses the challenges of retrofitting buildings for solar energy and will make the adoption of solar more economical for industrial building owners.

We often think of solar installations as ‘one and done,’ but the true lifespan of silicon solar panels is more like 10 years. Older solar installations are aging out.

Silicon-based solar technology is difficult to recycle, leading to impending environmental issues as these systems reach the end of their life. In complete contrast, Kardinia Energy’s printed solar panels are 100% recyclable.

The technology can operate off-grid, which is particularly beneficial for remote communities and industrial operations that rely on higher-cost energy sources.

The printed solar panels are also compatible with existing solar infrastructure and can be used in both grid-connected and independent systems.

Kardinia Energy’s panels are currently produced using the R2R print facility at the ANFF-Materials University of Newcastle Hub, but their success to date means they need more panels than the pilot manufacturing line can produce.

Kardinia Energy is partnering with the Trailblazer for Recycling and Clean Energy (TRaCE) to build Australia’s first printed solar manufacturing facility in Newcastle – a proof-of-concept for scaled-up manufacturing production. ANFF-Materials will help with the transition and the transfer of knowledge from ANFF engineers to Kardinia Energy employees and will continue to support the development and innovation of the infrastructure required for ink synthesis and characterisation of solar harvesting materials.

The impact of the new Kardinia Energy R2R solar panel print facility in the Hunter Valley will be felt across the Australian manufacturing sector, leading to the creation of numerous skilled employment opportunities and opportunities for new companies. The facility will also foster innovation across the organic electronics sector and support translation of novel technologies to commercialisation.

To learn more about Kardinia Energy, visit https://kardiniaenergy.com.

Published 15 October 2024 in ANFF’s 2024 Casebook ‘ANFF NEXT‘

Posted: 11 November 2024