Global water stress demands new technologies for the purification of different water resources.

The United Nations 2030 Agenda for Sustainable Development lays out 17 goals to obtain peace and prosperity for all people and the planet, chief among which is a commitment to clean water and sanitation. We need to ensure clean water and sanitation while maintaining the health of water-related eco-systems and providing relief for over 733 million people living in countries with high and critical levels of water stress.

As demonstrated in these two case studies, ANFF plays a critical role in supporting cutting-edge research programs that imagine innovative solutions to water purification and water treatment, helping researchers turn their ideas into accessible products that will directly impact people’s lives around the world.

A super-efficient, portable 3D solar evaporator developed by University of South Australia researchers will enable vulnerable communities to access reliable and affordable fresh drinking water from previously unusable water sources.

Using sunlight as an energy source, A/Prof. Haolan Xu and Dr Xuan Wu from UniSA’s Future Industries Institute in collaboration with ANFF-SA have developed a novel solar evaporation technique to derive fresh water from sea, brackish or contaminated water. Current solar evaporators are rather energy-inefficient, with 10 to 20% of incoming energy wasted in warming the bulk water and surrounding environment rather than evaporating the water.

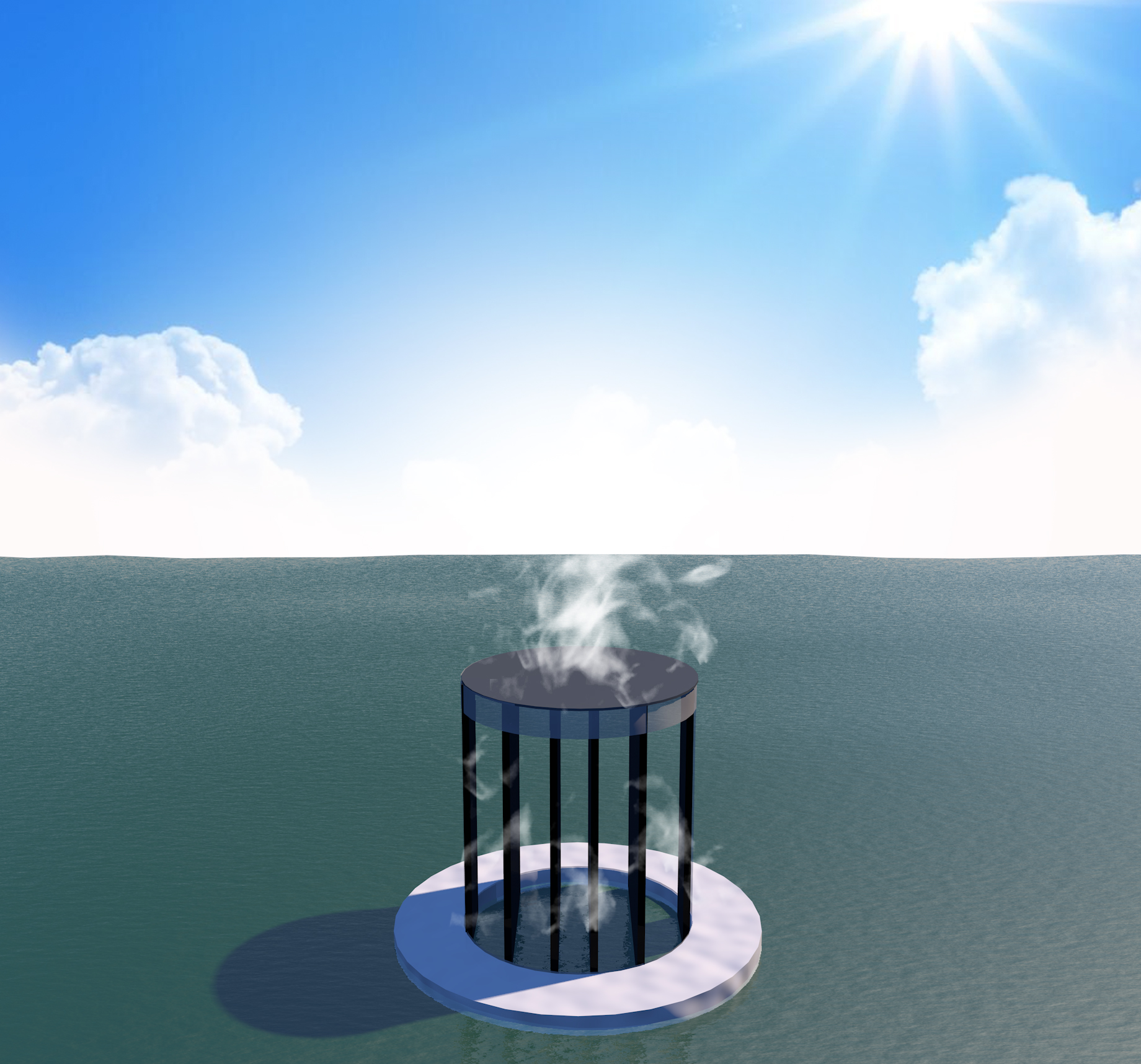

Easy to set up and made of materials almost entirely sourced from a local supermarket, the key to the technology’s heat absorption is in the innovative design of the 3D evaporator. Their device includes a photothermal fin-like structure that sits on the water surface. Constructed of fabric material, water is transported via wicking through the fins to the top evaporation surface. At this top surface, sunlight is converted to heat, rapidly evaporating the thin film of water.

Mimicking the ocean-surface evaporative processes of the natural water cycle, their 3D solar evaporator provides clean water solutions that are cheap, free to run, and require minimal maintenance. Its heatsink-like evaporator not only effectively prevents heat energy loss from the evaporation system, but it actually extracts a large amount of energy from the bulk water and surrounding environment to boost evaporation.

At current rates, in 2030 2.8 billion people will lack safely managed sanitation. New membrane technology developed by Deakin University researchers will revolutionise the filtration capabilities of wastewater treatment plants.

Wastewater is a polluted form of water generated from human activity and storm runoff. Through a combination of various physical, chemical and biological processes, a wastewater treatment facility removes contaminants from the water to create purified water that can be reused or released into the surrounding environment.

Particle filtration, which separates out solids larger than one micron, is one of the first treatment steps. However, particle filters are not sufficient to obtain required purification levels. To obtain the highest water quality, membrane filtration systems are used due to their high separation efficiency. Obviously, the material composition used in the membrane plays a critical role during the separation process since it governs the interactions between the membranes and different water pollutants. Membrane interface engineering is therefore a powerful approach to tailor the function of the membrane and optimise the separation performance.

Ahmed Rashed, a PhD student of Prof. Joselito Razal in Deakin University’s Institute for Frontier Materials (IFM), in collaboration with Lintec of America, Inc.; the Melbourne Centre for Nanofabrication and ANFF-Vic, uses atomic layer deposition (ALD) to redesign and fine tune the properties of filtration membrane surfaces, including thickness, pore size and surface charge. IFM’s innovative tin (IV) oxide-carbon nanotube (SnO2-CNT) technology extends membrane function beyond simple separation to catalytic, anti-viral, and self-cleaning properties. Their novel membranes simultaneously separate and degrade chemicals such as pharmaceuticals and viruses in water outflow without diminishing filtration performance.

The Razal group’s use of ALD to tailor and manipulate CNT membrane surfaces will shed light on the engineering of high-performance catalytic membrane treatment reactors, taking us one step closer to fulfilling the UN Sustainable Development goals with low cost, high-efficiency water purification.